FMEA Training Risk

Analysis

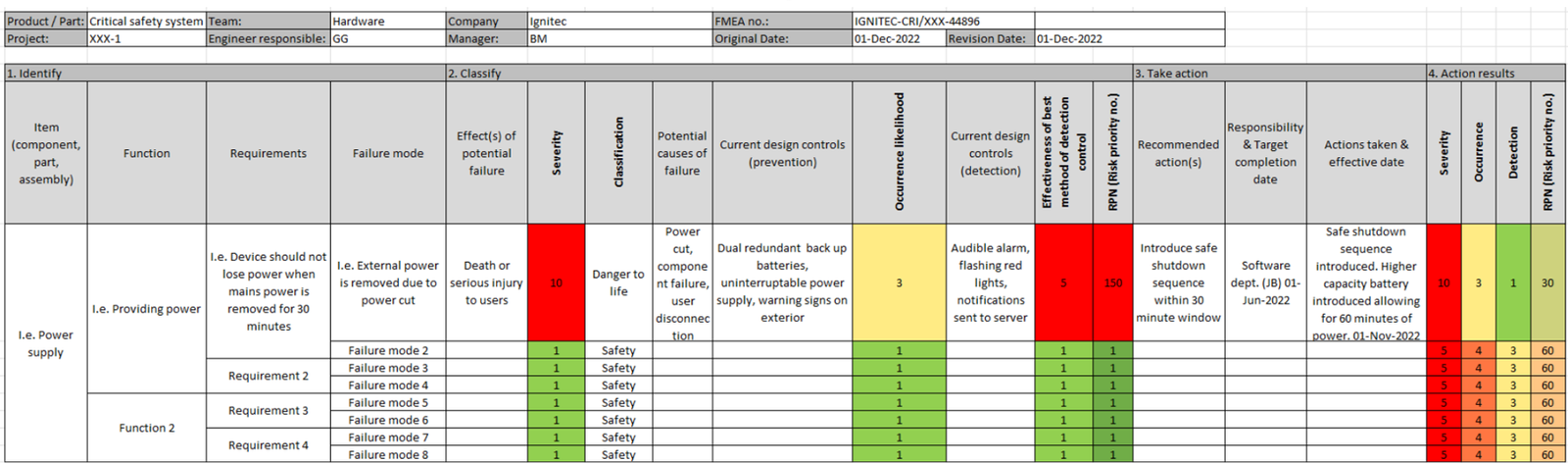

Failure Modes and Effects Analysis (FMEA) is a proactive method used in developing new products and processes to detect, manage, and prevent potential causes of failure. It helps reduce the impact of errors or faults, ensuring that risks are identified and addressed early in the design phase.

DFMEA (Design) helps ensure the product design meets all customer requirements and safety standards, while PFMEA (Process) plans the manufacturing process in cuch a way that it can consistently produce defect-free products.

FMEA Basic Training

- Designed for Design and Production Processes, this training focuses on executing FMEA to uncover potential risks affecting functionality, legality, safety, and production stability.

- By the end of this training, your team will be equipped to carry out FMEA analysis, identifying and addressing risks efficiently.

FMEA Moderator Training

- This training helps moderators learn how to guide FMEA sessions, document processes, and assess risks in a structured manner.

- Participants will gain skills to ensure accurate execution and documentation of FMEA methodologies and templates.

Benefits of FMEA training

- Risk Anticipation & Mitigation

- Cost Savings

- Preventive Action Mindset

- Improved Product and Process Quality.

- Compliance with Industry Standards

- Improved Decision-Making

- Enhanced Problem-Solving Skills

- Cross-Functional Collaboration

For more information, Contact Us

Request your complimentary consultation now